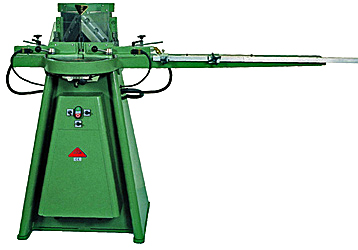

Morso Model EHT mitring machine is exactly the same machine as the Morso EH, with the same technical data and working capacities. BUT it is about 50 percent faster than the EH machine. The motor of the EHT is 1.5 kW, three phase. The EHT machine is only available in three phase electricity, voltage to your requirements.

In principle Morso EHT does the same work as the Morso F, but with the Morso EHT you have your work done automatically by pushing two push buttons. The Morso EHT is safe to operate as you must activate both push buttons at the same time to have the machine work, and therefore you cannot get your fingers underneath the knives. With the Morso EHT you can do production all day long.

If you compare the Morso EHT to a double mitre saw, you will find that first of all the cut with a saw is not as clean and accurate as with the Morso EHT. Secondly, there will very often be a problem with the dust from the saw.

On Morso EHT there is no dust, as the waste of the moulding is lead straight to the ground, which means it is not necessary to buy and expensive dust extractor.

Another thing is the waste of the moulding. By using a mitre saw, there will always be about one centimetre of waste per cut, but if you use the Morso EHT the waste is minimized to about 1 mm per cut.

A difference to one centimetre may not sound of much, but if the number of cuts are 200 per day, the unnecessary waste of mouldings is 200 cm per day, which is about 520 meters per year..... ( Working 5 days a week.... ).

The Morso EHT is supplied with the same standard equipment as the Morso F, plus it has:

- extension table to the left side,

- automatic rebate support and moulding clamps,

- measuring scale 1,500 mm with two adjustable stops - you can cut the short and long length of a frame without having to re-adjust the measurements,

- automatic cutting cycles for both large and small mouldings - which means that the machine always does the trim cut which is very important,

- adjustable length of stroke ( 3 positions ).